The ännt BARRIER K12 is a heavy-duty hydraulic security barrier engineered for locations that demand reliable vehicle-stopping performance. Designed for passage widths up to 6 meters, it provides a moving barrier height of 1100 mm above ground and comes in standard lengths of 3, 4, 5, and 6 meters. The system is certified to the highest international standards, including M50, K12, PAS 68, and IWA 14-1, making it suitable for government facilities, industrial sites, logistics hubs, and high-risk access points.

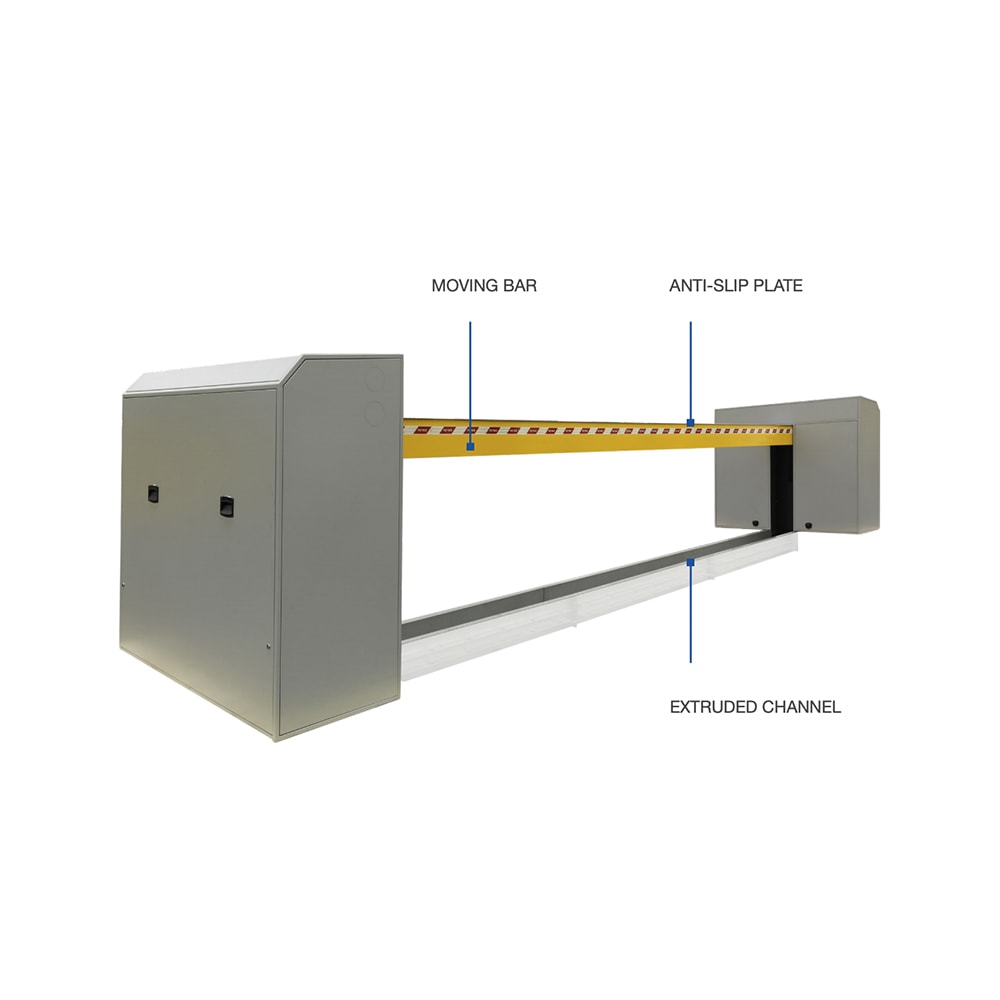

The barrier operates at a lifting and lowering speed of 15.7 cm/s and is designed for demanding environments, supporting up to 2,000 cycles per day with a service life of roughly 3,000,000 cycles. Its construction includes an anti-slip stainless steel top plate and a corrosion-protected body with standard painting, with custom RAL finishes available for the side columns. Rated to withstand 2,000,000 joules of impact energy with destruction, the unit provides exceptional breakout resistance.

Built for real-world conditions, the ännt BARRIER K12 operates from −40 C to +70 C when equipped with the required heating element for low temperatures. It uses a PLC-based control unit for dependable automation, and can be equipped with a 2-second EFO (Emergency Fast Operation) function, manual operation capability during power failures, and LED lighting strips for visual guidance. The result is a robust, high-security barrier system designed to perform consistently in demanding, mission-critical environments.