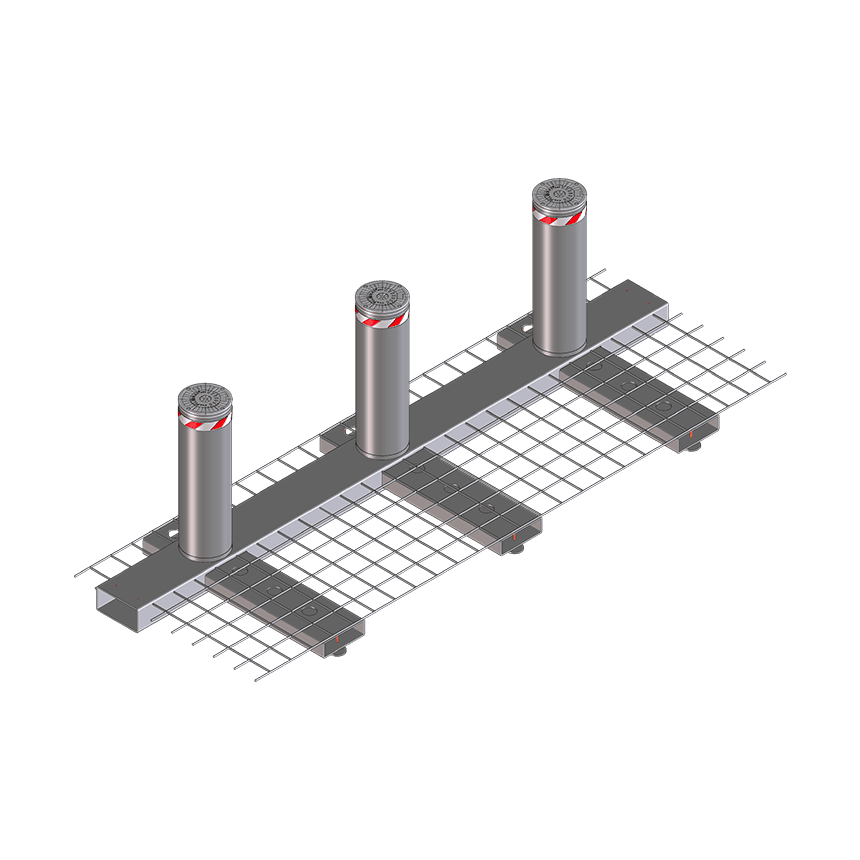

The FXSF275K4 900 is a fixed, shallow-foundation, crash-rated bollard designed for installations where shallow mounting is required — such as sites with underground utilities, parking garages, or other masked sub-surface constraints. The “SF” stands for “shallow foundation,” indicating this model uses the slimmest laying depth in its product line, making it ideal when standard deeper embedment isn’t feasible.

This bollard represents decades of design and manufacturing experience, combining structural strength, crash resistance and installation flexibility.