The ännt RM150/C40-900 is a removable high-security bollard designed for sites needing certified impact protection with the flexibility of complete access when required. Tested to ASTM F2656 at the C40 rating level, this model is engineered to stop a passenger vehicle traveling at 40 mph, making it a strong solution for commercial, municipal, and sensitive access-controlled environments where moderate crash protection is required.

This 900 mm bollard locks securely into a reinforced ground fitting using a profile cylinder lock. To remove it, the operator loosens the top retention screw, attaches the lifting eye, unlocks the mechanism, and lifts the cylinder free using the integrated handle. When removed, the recessed base remains flush with the surface, allowing vehicles or equipment to pass through without obstruction.

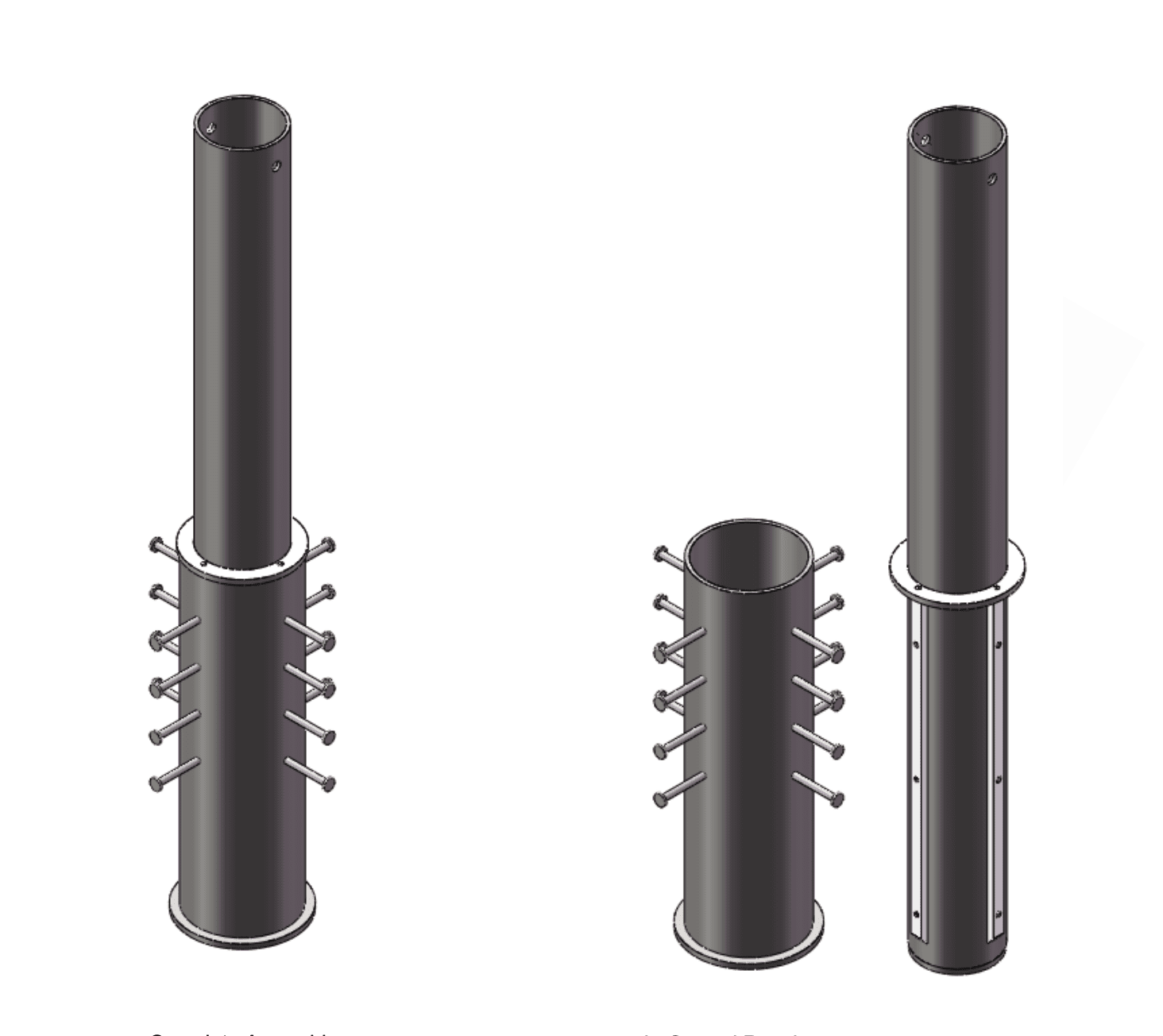

The RM150/C40-900 uses a compact reinforced foundation structure designed to deliver certified stopping performance while maintaining easier installation than higher-rated systems. Built with durable steel and a protective finish, it performs reliably in outdoor conditions and integrates cleanly with other ännt perimeter-security products for coordinated site layouts.

With certified impact resistance, secure locking, and full-removal capability, the RM150/C40-900 offers a practical balance of protection and access flexibility.